Every detail went through a rigorous design process.

Bubble tea is always the answer.

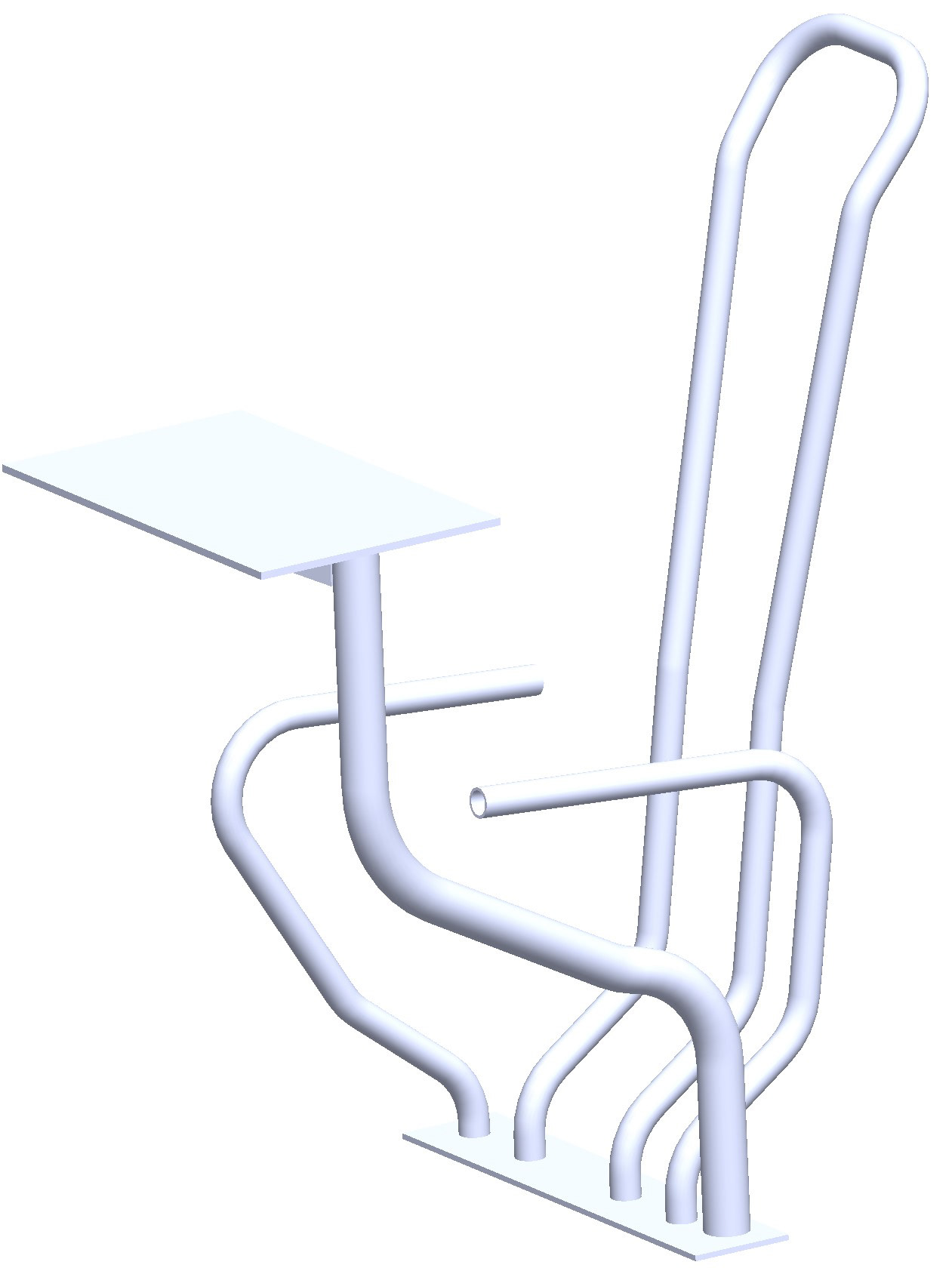

The accuracy of the tubing presented one of the largest challenges because it positions all of the chairs' touch points. Furthermore, the team had to ensure the proper ergonomics were met while integrating the steel tubing into the concrete base. Initial solutions included drilling holes in the cured concrete for the tubing, or embedding metal sleeves into the concrete. The final design direction employed a steel base plate that was welded to the tubing. The base plate allowed the team to dial in the chair measurements before casting began. The entire metal structure was then cast into the concrete.

Initial tubing design (some further modification were made)

Tubing design after concrete casting

Solidworks was used to develop technical drawings. These technical drawings were printed at full scale and allowed the team to create an accurate sketch model. Corrections discovered from building the sketch model were then implemented and the design was sent to metal fabrication companies.

A heat gun allowed the sand filled acrylic tubing to be bent to fit the technical drawings.

All the tubing was affixed to the base plate using solvent.

The acrylic tubing assembly was then spray painted silver.

Overall the sketch model was a success. The insight gained through the model allowed the team to make some critical changes. A few of these changes included reducing the seat height, shifting the tablet closer to the user, and redesigning the base to remove the 'wings' at the bottom.